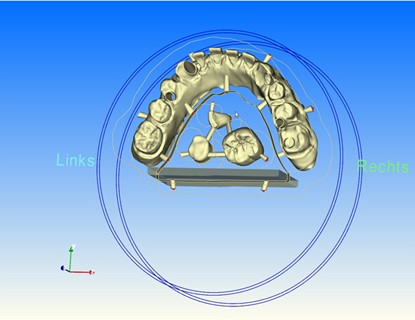

Dental CAD/CAM technology has revolutionized the dental industry, providing efficient and precise digital workflows for designing and manufacturing dental restorations. Despite these advancements, dental professionals often encounter challenges when milling their meticulously designed restorations. This article delves into common issues encountered during the milling process and emphasizes the importance of selecting the right CAM software to overcome these challenges in dental CAD/CAM technology.

Design Considerations

When difficulties arise in milling designed restorations, assessing the capabilities of your chosen CAM software is crucial. Reliable CAM software should offer advanced design tools that consider milling limitations during the design process. Key features to look for include:

- Undercut Management: Ensures that the design accounts for areas that the milling machine cannot reach, preventing errors during milling.

- Material Thickness: The software should allow for precise control over material thickness, ensuring the final restoration is both functional and aesthetic.

- Restoration Geometry: Compatibility with your milling system is essential, and the software should accommodate the complex geometries of dental restorations.

By addressing these design considerations within the CAM software, dental professionals can minimize issues during the milling process.

Material Compatibility

The CAM software you choose should offer comprehensive material libraries and parameters, enabling you to select the appropriate material for your dental restorations. Each material has distinct milling requirements, and the software should provide accurate data and settings specific to the chosen material. Key points include:

- Material Libraries: Extensive libraries that include various dental materials such as ceramics, zirconia, and composites.

- Accurate Parameters: Precise settings for each material to ensure optimal milling conditions.

- Customization: Ability to modify material parameters based on specific restoration needs.

Ensuring proper material selection within the CAM software enhances the milling process and increases the likelihood of successful results.

Tooling Optimization

An important aspect of CAM software is its ability to optimize toolpaths for efficient milling. The software should offer a range of milling tool options and allow for customization of toolpaths based on the restoration's geometry and material properties. Consider the following:

- Toolpath Strategies: Advanced strategies that cater to different restoration designs.

- Tool Selection: Options for various milling tools to achieve the desired precision.

- Customization: Flexibility to adjust toolpaths for specific restoration requirements.

Choosing CAM software with robust tooling optimization capabilities can significantly impact the milling process, resulting in precise and accurate restorations.

Integration and Compatibility

Compatibility between the CAM software and your milling machine's software is critical for seamless operation. It is essential to choose CAM software that is specifically designed to work with your milling system. This ensures:

- Smooth Data Transfer: Minimizes errors during the data transfer process.

- Maximized Milling Precision: Ensures the milling machine operates accurately based on the design data.

- Efficient Workflow: Streamlines the entire milling process from design to final restoration.

Integration and compatibility are key to achieving successful milling outcomes.

Updates and Support

Selecting CAM software from reputable providers ensures access to regular updates, bug fixes, and new features that enhance the milling experience. Consider:

- Regular Updates: Keeping the software up-to-date with the latest features and improvements.

- Technical Support: Access to prompt support to address any issues that arise.

- Resource Availability: Comprehensive training materials and resources to enhance user proficiency.

Staying up-to-date with the latest software releases and taking advantage of ongoing technical support ensures continuous improvement in the CAM software's functionality and compatibility.

User-Friendly Interface and Training

Ease of use and a user-friendly interface are essential when choosing CAM software. A software package that offers intuitive navigation, clear toolpath visualization, and user-friendly controls can streamline the milling process and reduce the learning curve. Important aspects include:

- Intuitive Navigation: Easy-to-use interface that simplifies the design and milling process.

- Toolpath Visualization: Clear visualization of toolpaths to ensure accurate milling.

- Comprehensive Training: Access to training materials and support to enhance user proficiency.

By choosing user-friendly CAM software, dental professionals can optimize their milling processes and achieve better results.

Popular Dental CAM Software Brands

Several reputable CAM software brands are widely used in the dental industry. Some of the popular options include:

- Planmeca Romexis

- exocad DentalCAD

- 3Shape Dental System

- Dental Wings DWOS

- Sirona inLab

- Roland DWX Software

- Delcam DentCAD

- CIMsystem Sum3D Dental

- Amann Girrbach Ceramill

- VITA CAD/CAM

- Ivoclar Digital CAD/CAM

These brands offer a range of features and capabilities to address various design and milling challenges.

Conclusion

In the realm of dental CAD/CAM technology, selecting the right CAM software is paramount to overcoming challenges encountered when milling designed restorations. A reliable CAM software package offers design considerations, material compatibility, tooling optimization, integration with milling systems, regular updates, and user-friendly interfaces. By carefully evaluating and choosing the appropriate CAM software, dental professionals can optimize their milling processes, achieve precise and accurate restorations, and unlock the full potential of dental CAD/CAM technology in their practice.

To learn more about CAM strategies and find the right CAM software for your dental practice, consult the experts at our community. Visit our website at www.cadcammasters.com to explore our range of services.. Our community of experts is dedicated to helping you harness the power of digital dentistry and achieve exceptional results. Contact us today!

FAQs

Q: Why is my milling machine not producing accurate restorations?

A: The accuracy of restorations can be affected by several factors, including the compatibility of your CAM software with the milling machine, toolpath optimization, and the material selection. Ensure that your CAM software is up-to-date and properly configured for your milling system.

Q: How do I choose the right material for my dental restorations?

A: Select a CAM software that offers comprehensive material libraries and accurate parameters for each material. This ensures that you can choose the appropriate material for your restorations and achieve optimal milling results.

Q: What should I look for in CAM software for dental applications?

A: Key features to consider include advanced design tools, material compatibility, tooling optimization, seamless integration with milling machines, regular updates, and a user-friendly interface.

Q: How can I improve the precision of my milled restorations?

A: Optimize your CAM software's toolpath strategies and ensure proper integration with your milling machine. Regularly update the software and utilize comprehensive training resources to enhance user proficiency.

Q: What are some popular CAM software brands for dental applications?

A: Some popular brands include Planmeca Romexis, exocad DentalCAD, 3Shape Dental System, Dental Wings DWOS, Sirona inLab, Roland DWX Software, Delcam DentCAD, CIMsystem Sum3D Dental, Amann Girrbach Ceramill, VITA CAD/CAM, and Ivoclar Digital CAD/CAM.